Join Flexco at

Booth #1410!

Discover the latest developments in Heavy-Duty belt conveyor solutions in St. Louis at this year's AGG1!

See You in St. Louis!

The Flexco Heavy-Duty team is excited to see our fellow industry peers in St. Louis, MO for the highly anticipated AGG1!

Visitors of Booth 1410 can expect an unprecedented amount of access at this year's show as solutions like our belt cutters, skivers, and mechanical belt fastening systems will be available for hands-on product demos alongside our team of product experts.

To learn more about what and who you can expect to see at the show, check out our event information below!

Solutions On-Display at AGG1 2025

From new additions to old favorites, the Flexco Booth has a belt conveyor solution for everyone.

Discover some of what you can find at our booth below.

CBS Continuous Blade Secondary Belt Cleaner

The CBS Continuous Blade Secondary Belt Cleaner is designed with an unsegmented blade for excellent cleaning efficiency and low maintenance. The heavy-duty blade features a steel backbone holding a carbide leading edge which is encapsulated in our proprietary polyurethane to provide a long-wearing solution for your belt. When paired with a spring or air tensioner, the blade maintains constant pressure on the belt for excellent cleaning efficiency.

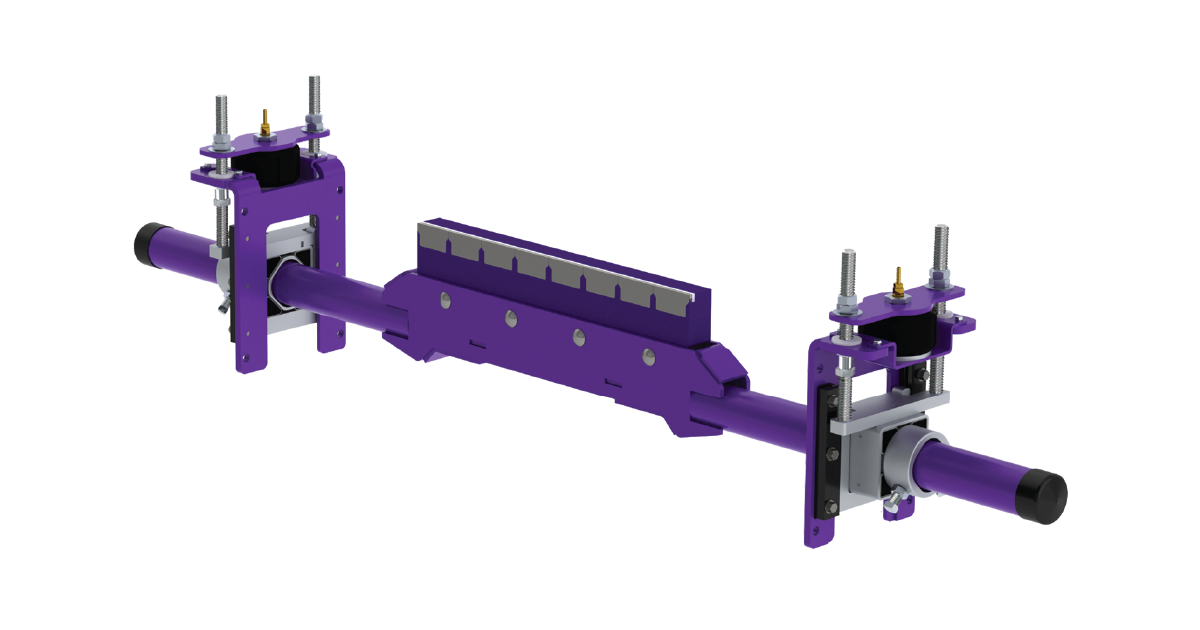

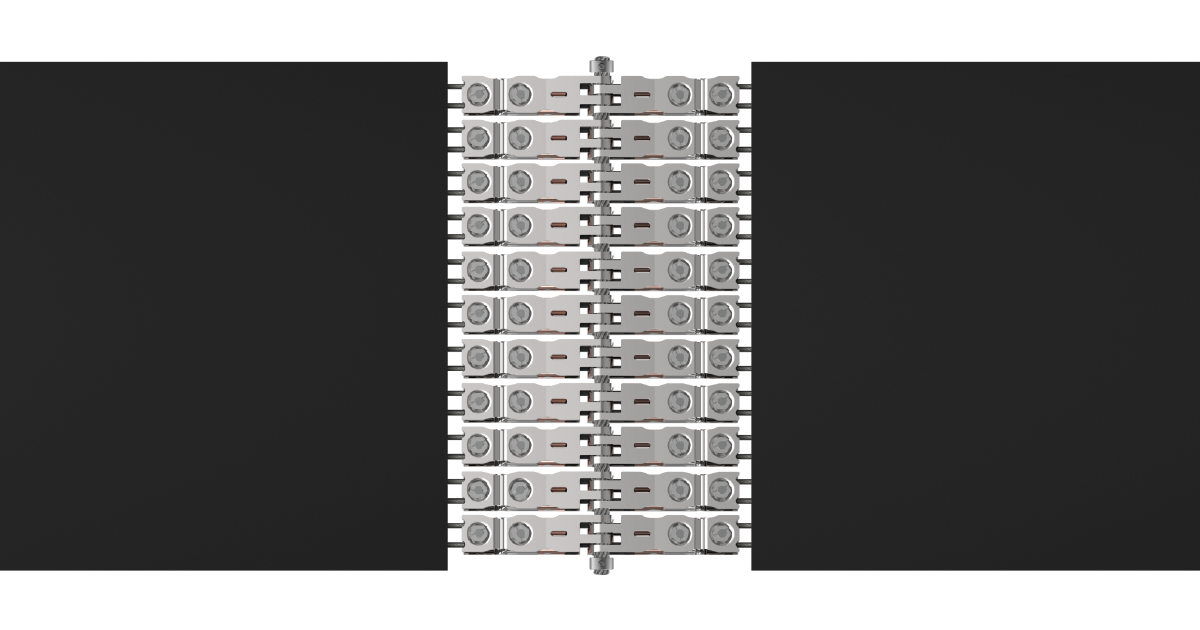

FXC™ Steel Cord Belt Fastening System

Available for Product Demo

When a heavy-duty belt conveyor system faces unexpected and increasingly costly downtime, the FXC™ Steel Cord Belt Fastening System from Flexco becomes the right choice. Whether a temporary splice needs to be installed while waiting for vulcanization or a belt needs to be pulled onto a conveyor system, the FXC™ is the ideal solution to keep on hand for quicker reaction to downtime incidents.

Enclosed Skirt Systems

Flexco’s Enclosed Skirting Systems provide an effective solution for containing material and controlling dust at conveyor load zones. Designed for universal mounting and easy installation, these systems feature standard skirting assemblies with adjustable mounting arrangements, reducing the need for complex measuring and engineering. Whether standard or customized, Flexco’s Enclosed Skirting Systems help operations maintain a cleaner, safer, and more efficient work environment.

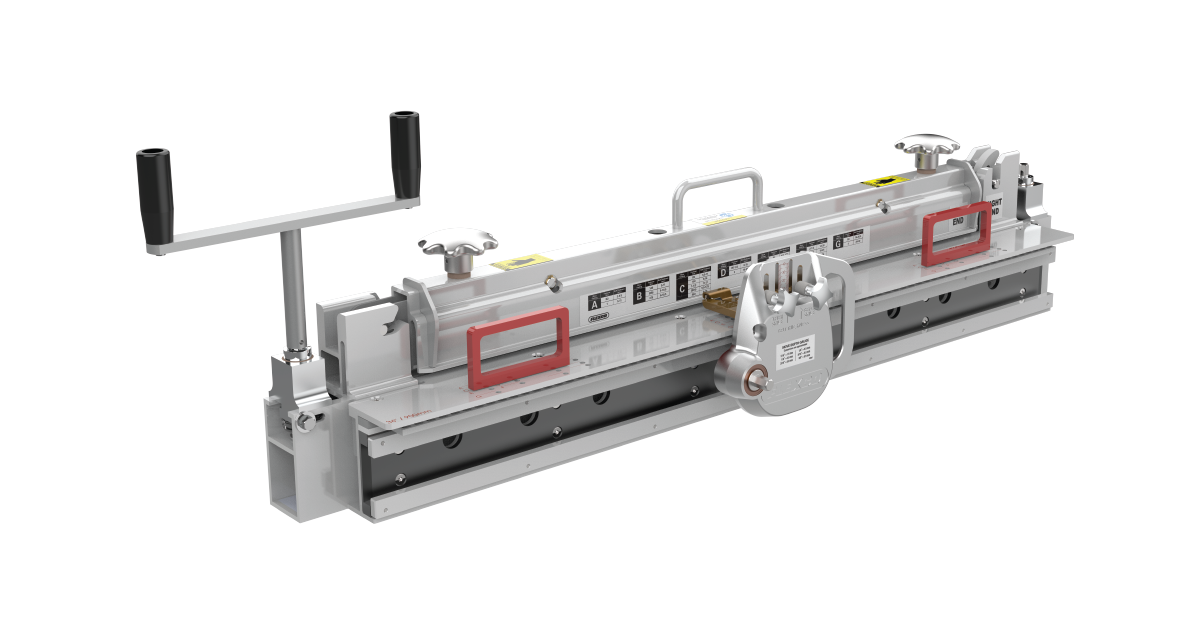

900 Series Belt Cutter/Skiver

Available for Product Demo

The 900 Series Belt Cutter/Skiver is an incredibly convenient two-in-one belt maintenance tool that helps to ensure more efficient and safer belt cutting and skiving. With customizable belt thickness settings, carefully engineered safety features and multiple options to drive the skiver, the 900 series is the ideal choice for operators to set their fastener installation up for success.

TUG™ HD® Belt Clamps

TUG™ HD® Belt Clamps provide a reliable and secure solution for safely clamping belts during maintenance and repair. Engineered to meet the most stringent safety standards, these heavy-duty clamps ensure even tensioning across the entire belt width for maximum strength. Available in 6- and 8-ton versions, their modular design enhances versatility and portability, making them an essential tool for maintenance teams in demanding applications.

Flexco Elevate®

Flexco Elevate belt cleaner monitoring lets operations remotely gather critical data and perform real-time analysis to boost efficiency, with intelligence that grows over time. Its predictive, data-driven engine lets customers move from traditional methods of monitoring cleaner performance to a new way that empowers operations for the future.

Our Heavy-Duty Industry Experts

When you partner with Flexco, you gain access to the industry's most dedicated team of industry experts.

Discover key members of our team below!

Travis Vliem

Product Manager

Vliem is responsible for the Flexco Elevate™ IoT platform – researching and designing business capabilities and go-to-market strategies, implementing and driving adoption of the program, assisting in researching and developing new sensing and monitoring systems, and capturing and evaluating the voice of the customer.

Kevin Fales

Product Manager

In the role of Product Manager, Fales manages the Belt Conveyor Product line, providing strategic guidance for the global business unit. This includes identifying product development opportunities and working with global engineering resources to create new product concepts and enhance existing products.

Franklin Moore

Product Manager

In the role of Product Manager, Moore is responsible for the market strategy for Flexco’s line of mechanical belt fasteners, the FXC™ Steel Cord Belt Fastening System, and the Minet Lacing Technology product line in the U.S., Canada, and Mexico, which includes the Super-Screw® line of fasteners and Fix’N Go® Rip Repair.

Aaron Wilson

Accounts Manager

In the role of Strategic Accounts Manager, Wilson supports our vision of maximizing belt conveyor productivity for our global strategic account customers and channel partners, all while helping to create an environment where talented employees of heavy-duty belt conveyor systems can better thrive & succeed on the job.

%20(1).webp?width=1200&length=1200&name=Image%20(5)%20(1).webp)

%20(1).webp?width=1200&length=1200&name=Image%20(6)%20(1).webp)

.webp?width=1200&length=1200&name=Image%20(7).webp)

.webp?width=1200&length=1200&name=Image%20(8).webp)

Follow Flexco at AGG1!

For up-to-the-minute updates of Flexco's presence from the show floor at AGG1, be sure to follow along on our social media channels!

Our subscribers will get a first-look at behind the scenes booth videos, new product demonstrations, fun Flexco team moments, and so much more.

If you visit us at AGG1, be sure to tag us on social media with #Flexco!

Check out our social media profiles below: