When it comes to maintaining a clean conveyor belt, industrial bakeries face a unique set of challenges — challenges that can be costly and time consuming.

Scroll down to see how the Flexco FGP Food Grade Primary Cleaner helped one industrial bakery reduce carryback and maintenance costs to increase production by $22,000 annually. Then complete our ROI calculator to discover what you could be saving at your commercial bakery.

Despite dry-steam cleaning on a continual basis during production, this industrial bakery was experiencing major carryback from chocolate sticking to the belt and building up on the backside of the conveyor and the inline sanitizing equipment. Then, they discovered the Flexco FGP Good Grade Primary Cleaner.

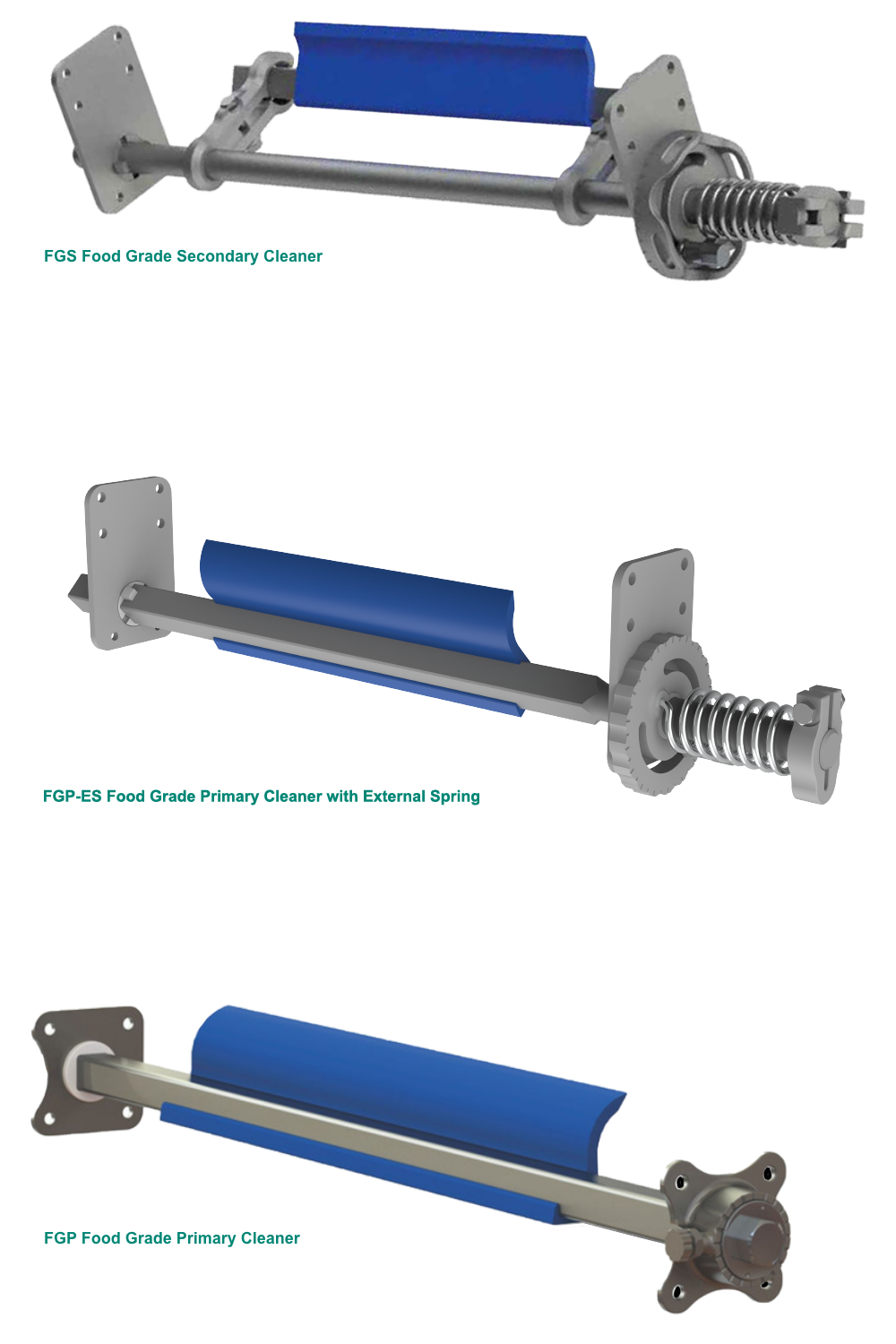

The FGP Food Grade Primary Cleaner, FGP-ES Food Grade Primary Cleaner with External Spring, and FGS Food Grade Secondary Cleaners from Flexco are easy to install, easy to maintain, and disassemble in under a minute for regular cleaning and sanitization. Along with their excellent cleaning efficiency, the cleaners feature stainless-steel components and food grade materials that limit crevices and opportunities for bacteria growth.

Chocolate from baked goods was sticking to the belt of the cookie, bread, and pastry line that is dry steam cleaned on a continual basis during production. This created extreme carryback problems for this industrial bakery. Conveyors had to regularly be stopped, washed, and sanitized to remove chocolate from the rollers and the maintenance team had to frequently clean the floor below the conveyor due to the wasted product carryback.

The Flexco FGP Food Grade Primary Cleaner offered a simple design, metal detectable UHMW blade, and stainless-steel components that allowed for effective removal of chocolate. The FGP limited carryback by more than 75%, keeping it from building up on the other conveyor components and from falling onto the floor. By positioning the FGP in front of the in-place dry steam cleaner in the direction of belt travel, the cleaner was also able to improve the efficiency of the steamer.

Thanks to the success of the FGP Food Grade Primary Cleaner, the commercial bakery realized $22,000 in increased production because of the reduced downtime needed for cleanup and sanitization. The team could also run the product line longer between cleanings.