Partner with Flexco on Your Next CapEx Project

Submit your specs or RFQ to get a tailored bid from our team of conveyor system experts.

Whether you’re expanding, upgrading, or solving a persistent conveying challenge, Flexco is ready to be your partner in productivity. Share your project details and let us show you why Flexco has been the industry leader for over a century.

Success Starts with the Right Partner From Day One

Capital expenditure projects are high-stakes, long-horizon investments that demand precision, planning, and the right partnerships from the very beginning. At Flexco, we specialize in supporting CapEx initiatives with engineered conveyor solutions that are designed to integrate seamlessly into complex project scopes — delivering long-term reliability, global support, and performance that’s purpose-built for the world’s most demanding industries.

From feasibility and front-end engineering to procurement and final commissioning, Flexco partners closely with EPCs, engineering consultants, and end users to ensure the materials handling portion of your project is done right the first time. Through early engagement with our technical experts, we provide guidance on product selection, layout optimization, and constructability — minimizing design revisions, reducing procurement delays, and eliminating costly site retrofits.

Flexco’s global presence means you get more than local support — you gain access to a connected network of project specialists, regional engineers, and logistics hubs across five continents. Our global supply capabilities help reduce lead times and ensure material consistency, while our engineering teams are equipped to reengineer standard Flexco products to meet even the most challenging or non-standard applications.

To streamline project execution, Flexco offers a single point of contact for CapEx bidding and delivery in every major region. Our project specialists act as internal navigators — coordinating engineering, manufacturing, and regional support to keep your project aligned with budget, timeline, and spec.

We don’t just deliver individual components — we deliver high-performing systems backed by decades of project experience, real-world data, and the flexibility to meet your site-specific demands. Whether you're designing a new plant, expanding an existing operation, or upgrading legacy systems, Flexco is your trusted partner throughout the full project lifecycle — helping you meet production targets, reduce total installed cost, and ensure your investment delivers from day one.

How We Support Your CapEx Success

From initial consultation through final commissioning, our comprehensive services ensure your conveyor system investment delivers maximum productivity and long-term value.

Products

Comprehensive conveyor system solutions engineered for your specific application requirements and operational demands.

Education & Training

Expert-led programs designed to maximize your team's knowledge and ensure optimal performance throughout the project lifecycle.

Early Engineering Consultation

Collaborate early with us to select the right products and solutions tailored for performance, reliability, and success across every stage of your project.

CAD Drawings/Renderings

Detailed technical drawings and 3D visualizations to support your design process and ensure seamless project integration.

Bid Proposals & Contracting

Comprehensive proposal development and contract negotiation services that meet your timeline and procurement standards.

Support & Servicing

Ongoing technical support, maintenance guidance, and troubleshooting assistance to maximize your long-term performance.

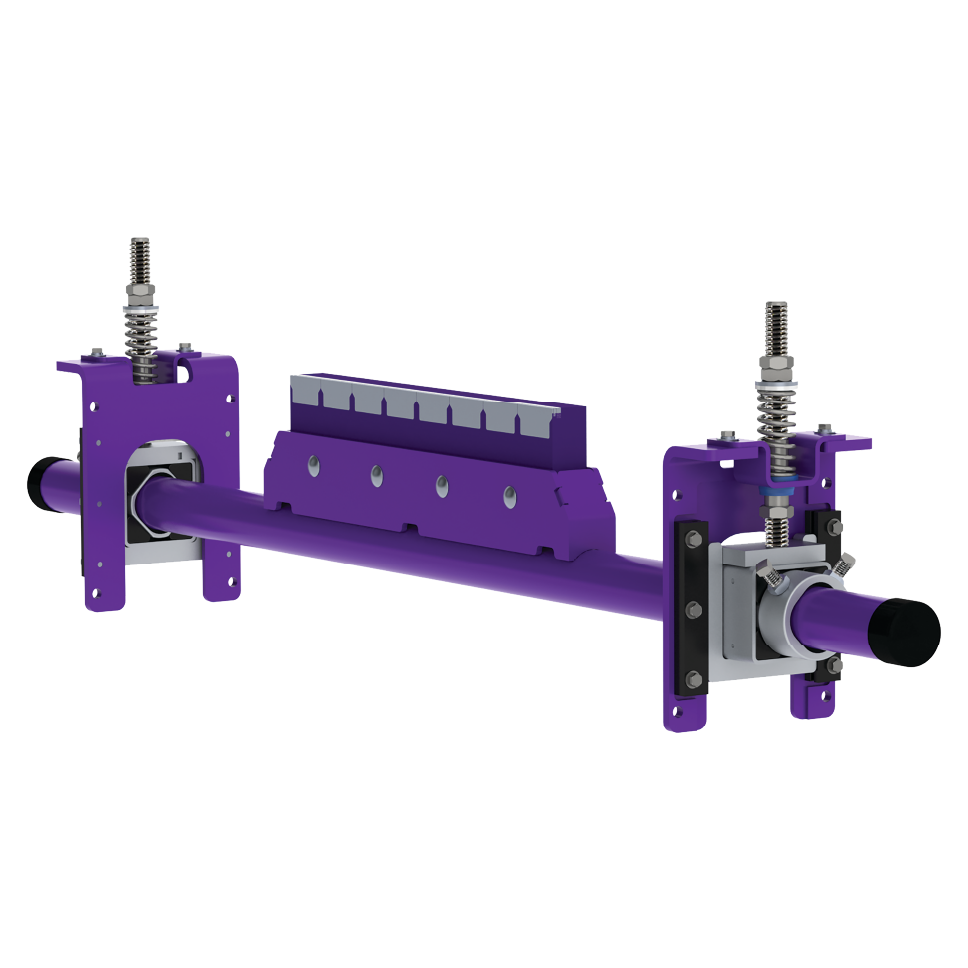

Precleaners

Mounted on the head pulley, precleaners help to remove up to 70% of carryback.

Belt Cleaner Accessories

Further enhance the capabilities of your belt conveyor cleaning systems.

Secondary Cleaners

Mounted just off of the head pulley, secondary cleaners remove over 90% of carryback.

Flexco Elevate®

Real-time data helps you expand the life of your Flexco belt cleaning systems.

Skirting Systems

Limit spillage and control dust emission to create an efficient, safe work environment.

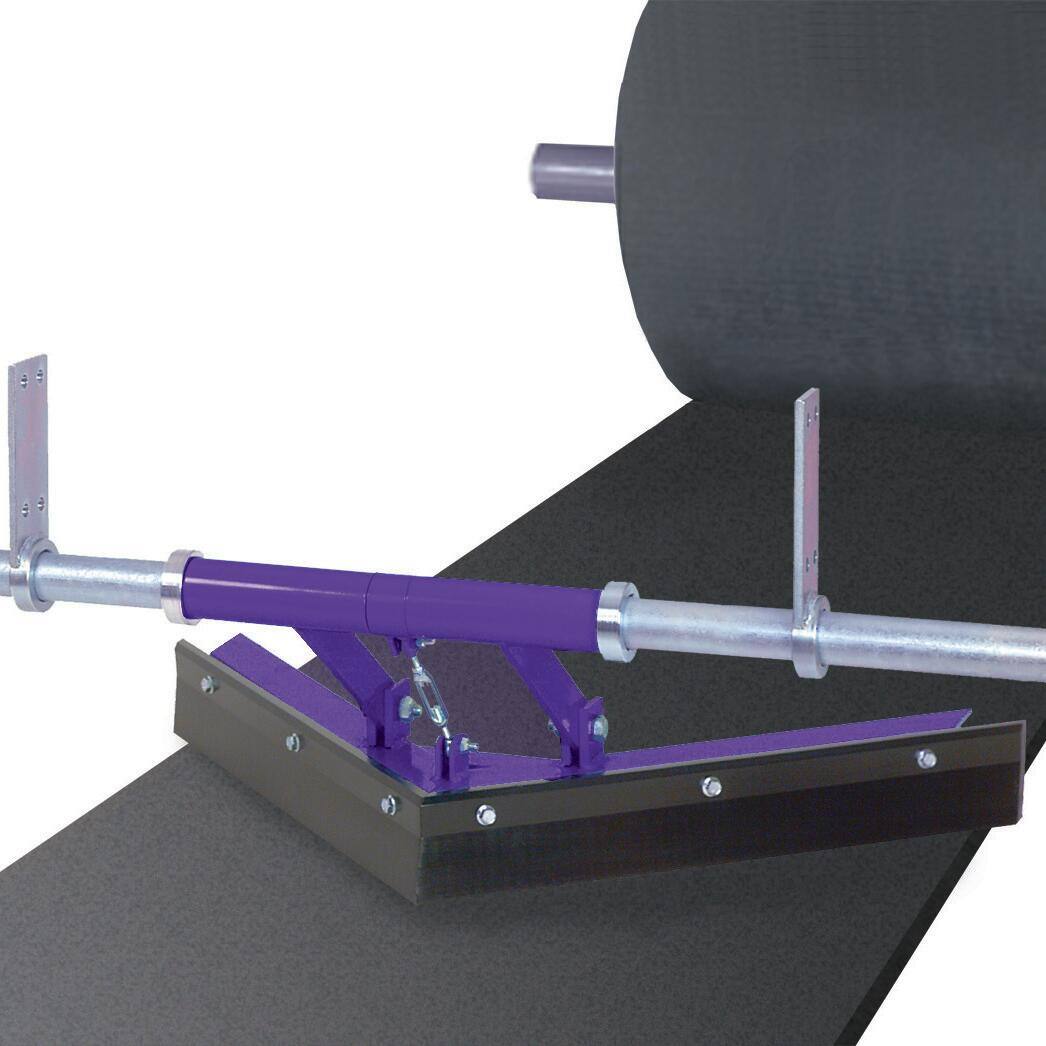

Belt Plows

Remove rocks and lumps on the return side of the belt to protect tail or take-up pulleys.

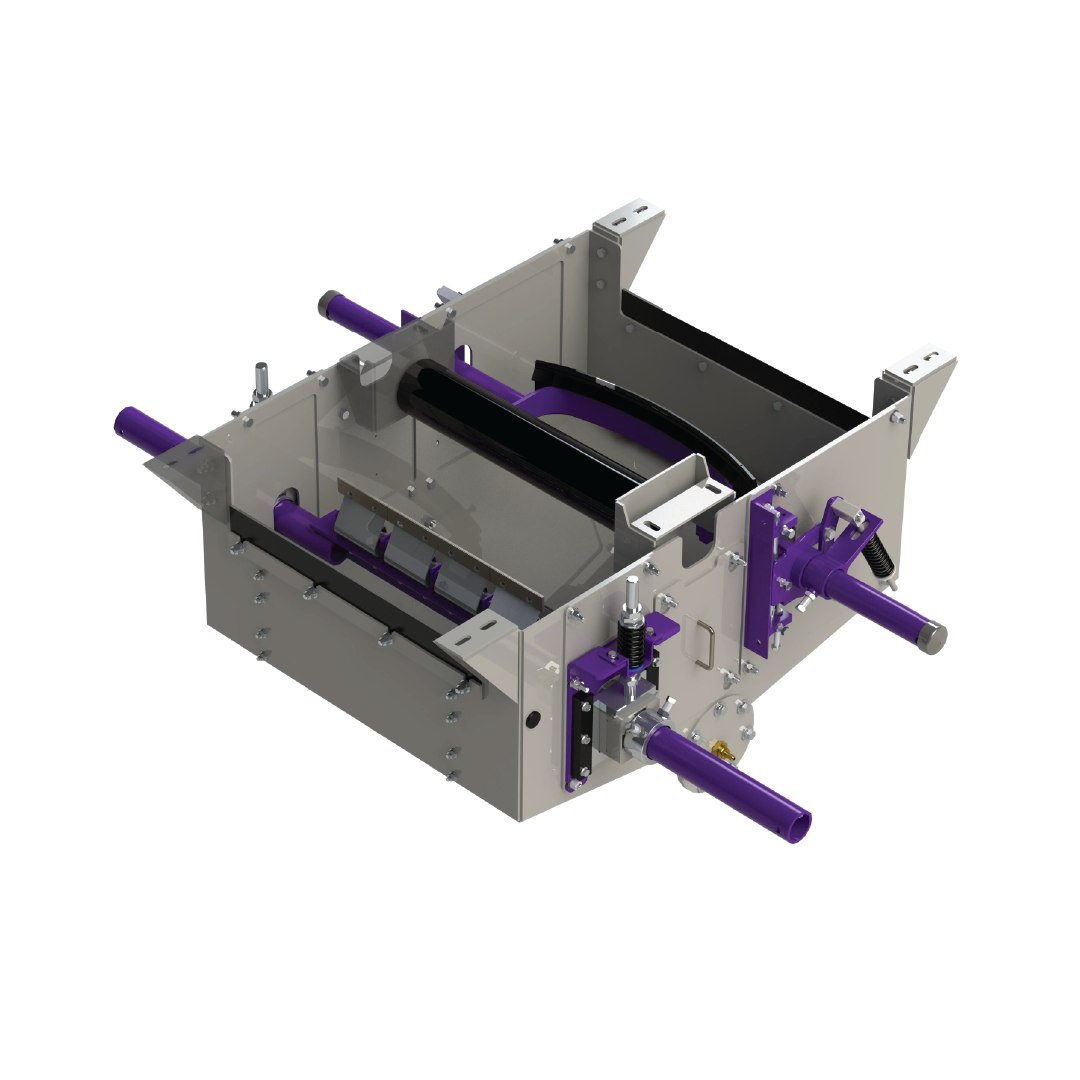

Slider/Impact Beds

Absorb the transfer impact of material, seal the load zone, and protect your belt.

Positioners & Trainers

Keep your belt from negatively impacting your structure and ensure material stays centered.

Mechanical Belt Fasteners

For the industry's most simple and effective belt fastening solutions, turn to Flexco.

Belt Maintenance Tools

Discover lifters, clamps, cutters, and skivers that make maintenance and installs a breeze.

Pulley Lagging

A strong belt grip helps improve productivity and efficiency, while also protecting the pulley.

.png?width=250&height=82&name=Flexco%20Corporate%20Logo%20Black%20(2).png)

Featured CapEx Projects

See how our CapEx solutions have transformed operations across industries, delivering measurable

improvements in productivity, efficiency, and cost savings for our clients.

Project Highlight

Minera Panamá – Panama

One of the largest copper mines in the world, the Minera Panamá operation required a conveyor belt cleaning system capable of performing in extreme tropical conditions, high-tonnage throughput, and across multiple plant areas.

Flexco was selected to supply all belt cleaners and plows across the site, working closely with the EPC and the owner during the early engineering and procurement phases. By engaging at the front-end of the project, Flexco ensured product standardization across the mine and plant, reduced long-term maintenance requirements, and supported the specification of high-performance cleaners capable of managing heavy carryback in wet, sticky environments.

Our global project team coordinated logistics and delivery through multiple countries, providing timely shipment to the Panama site while supporting on-site installation and commissioning. Flexco’s ability to adapt our cleaner designs to match unique pulley arrangements and mounting constraints helped the site avoid costly rework and meet its aggressive commissioning timeline.

Today, Flexco continues to support Minera Panamá with ongoing technical assistance, spare parts availability, and a trusted partnership that began with CapEx and has extended into full lifecycle support.

Project Highlight

FQML Sentinel – Zambia

The Sentinel Copper Mine, operated by First Quantum Minerals (FQML), is one of Africa’s largest and most technologically advanced copper operations. During the early stages of the project, Flexco engaged with both FQML and engineering firm Fluor to understand the site’s demanding load zone requirements and provide engineered impact protection that would perform under extreme throughput conditions.

Flexco supplied engineered Impact Beds across multiple transfer points at the Sentinel site, customizing each unit to suit specific belt widths, loading geometries, and structure constraints. Our early involvement during the CapEx planning and engineering phase ensured the impact protection was fully integrated into the conveyor design, eliminating the need for retrofits or field rework during installation.

By working hand-in-hand with the project teams, Flexco was able to reengineer standard impact bed designs to account for the high drop heights, wide belts, and challenging material characteristics at the site. Our global supply capabilities ensured timely delivery to this remote Zambian location, supporting Fluor’s construction timeline and FQML’s commissioning schedule.

Flexco continues to provide technical support and aftermarket guidance to the Sentinel site, further reinforcing our role as a trusted partner from project concept through ongoing operation.

Project Highlight

Westshore Terminals – Canada

Flexco is currently engaged in the supply of key conveyor components for the Westshore Terminals Expansion Project in British Columbia, one of Canada’s major bulk material export hubs. Since 2023, Flexco has been working closely with Jacobs Engineering during the front-end engineering and design (FEED) phases to ensure alignment on technical specifications, material handling performance, and long-term maintainability.

As part of this ongoing CapEx collaboration, Flexco has provided engineering consultation, product recommendations, and 3D model integration for a range of belt cleaners, plows, and impact systems to be installed across critical conveyor lines in the expansion.

Our team’s early engagement has enabled Jacobs and the project stakeholders to standardize product types across the facility, reduce engineering revisions, and ensure installation feasibility during the construction phase. With global engineering support and North American manufacturing, Flexco is positioned to deliver components that meet both project performance requirements and lead time expectations.

The Westshore project demonstrates Flexco’s commitment to proactive collaboration, engineering flexibility, and regionally coordinated project support — with full execution continuing through 2025.

Project Highlight

Skouries – Hellas Gold, Greece

Flexco is proud to support the Skouries Project in northern Greece — a high-profile gold and copper development led by Hellas Gold, a subsidiary of Eldorado Gold. This advanced-stage project features both open pit and underground mining operations and is expected to become a key contributor to Europe’s critical mineral supply chain.

Flexco was selected to supply a large volume of belt cleaners across the site’s extensive conveyor system, working closely with EPC contractor TNT (Chile) during the detailed engineering and procurement phases. Our engagement focused on product standardization, performance durability, and long-term maintainability to support Skouries' high-capacity material handling needs.

With complex logistics involving coordination between Latin America and Europe, Flexco’s global project team ensured seamless technical alignment and supply chain execution. The selected belt cleaners were tailored to meet the project’s site-specific conditions, ensuring reliable performance under demanding throughput and environmental conditions.

Flexco’s involvement in the Skouries project reflects our ability to support global CapEx developments across regions — connecting engineering firms, owners, and site operations with engineered conveyor solutions that deliver both performance and lifecycle value.

Meet the Team Behind Your Success

Our experienced professionals bring decades of industry expertise and a customer-first approach to ensure your conveyor system project is delivered on time, on budget, and exceeds your operational expectations.

Aaron Wilson

Strategic Accounts Manager

awilson@flexco.com | (904) 468-2071

With over 20 years of proven experience as a territory manager, Aaron brings deep industry expertise and a customer-first approach to every CapEx project. He holds a Master's Certificate from NIBA (National Industrial Belting Association) and a Yellow Belt Certification from the Lean Solutions Academy, giving him comprehensive knowledge of industrial conveyor systems and lean implementation strategies. Aaron understands that successful conveyor system projects require more than technical knowledge—they demand a partner who can navigate complex requirements, tight deadlines, and budget constraints while delivering results that exceed expectations.

What sets Aaron apart is his ability to translate two decades of hands-on customer relationship experience into actionable project strategies. He excels at building strong partnerships with strategic accounts and channel partners, ensuring every stakeholder feels confident in their investment. When you work with Aaron, you're partnering with someone who has successfully guided hundreds of conveyor system projects from initial consultation through final commissioning, always focusing on delivering measurable improvements to your operational productivity and bottom line.

Joseph Allen

Global Projects Implementation Manager

jallen@flexco.com | (630) 432-5121

Joseph Allen leads Flexco’s global strategy for capital project engagement, specializing in aligning the company’s capabilities with large-scale mining and infrastructure developments around the world. With over a decade of experience in operational leadership and investigative roles — including time with Metropolitan Police Scotland Yard - London and U.S. federal agencies — Joseph brings a rare mix of strategic vision, technical curiosity, and relentless problem-solving to every project.

His background in high-pressure, detail-critical environments sharpened his ability to cut through complexity, align stakeholders, and drive results; qualities that now define his work across global CapEx initiatives. Joseph works closely with EPCs, end users, and Flexco’s global teams to identify early-stage opportunities and ensure our conveyor solutions are built into project specifications from the ground up.

He is currently leading the global rollout of Salesforce Projects — driving improved visibility, bid coordination, and RFQ/RFP alignment across all regions. Known for his hands-on style and direct approach, Joseph helps simplify complex challenges and brings clarity to fast-moving project environments. His work ensures Flexco’s global CapEx projects are executed with precision, professionalism, and long-term value in mind.

_1080cropped.png)