Flexco Impact & Slider Beds

When it comes to load zones, Flexco impact and slider beds deliver the highest level of material containment and belt protection. They have been specially designed to control acceleration, deaden impact energy, reduce damaging vibrations, and extend belt life. But most of all, they have been engineered with unmatched serviceability with a slide-out service making maintenance efficient and safe for operators.

Success Story

South Australia Quarry Decreases Maintenance Time and Increases Productivity with Custom DRX4500 Impact Bed

PROBLEM

The original impact bed installed was not strong enough to support the extreme tonnages, damaging idler frames frequently, and creating mass spillage and constant belt replacements.

SOLUTION

As the impact energy was greater than the acceptable standard of the DRX300 Impact Bed, we designed and manufactured a custom DRX4500 Impact Bed in Australia.

RESULTS

![]()

The belt could now run 24/7 and the operation could perform planned maintenance and scheduled shutdowns, significantly increasing their output.

Download a copy of the full case study

In the Field

.jpeg?width=1008&height=756&name=Resized_20210619_145915(1).jpeg)

Flexco Impact & Slider Bed Range

Features & Applications

With long-lasting UHMW slider bars, combined with high-performance rollers, the Flexco Slider Bed effectively seals the load zone and minimizes drag on the belt.

- Adjustable trough angles: 20°, 35° or 45°

- Bed rating: No impact

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Sealing of extended load zone

With long-lasting UHMW slider bars, combined with high-performance rollers, the Flexco Slider Bed effectively seals the load zone and minimizes drag on the belt.

- Adjustable trough angles: 20°, 35° or 45°

- Bed rating: 25kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Sand and Gravel

Designed with rubber and UHMW impact bars to absorb the impact of falling material, long-wearing UHMW outer slider bars to seal the load zone, and adjustable trough angles for ease of service. Can be paired with Flexco Slider beds.

- Adjustable trough angles: 20°, 35° or 45°

- Bed rating: Up to 25kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Sand and Gravel

Designed with rubber and UHMW impact bars to absorb the impact of falling material, long-wearing UHMW outer slider bars to seal the load zone, and adjustable trough angles for ease of service. Can be paired with Flexco Slider beds.

- Adjustable trough angles: 20°, 35° or 45°

- Bed rating: 25- 100 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Hard Rock Mining and Limestone Quarrying

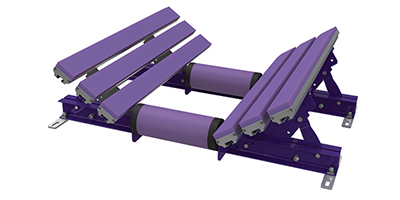

Exclusive Velocity Reduction Technology™, Impact Bars and Isolation Mounts deaden rebound forces for reduced spillage and material degradation. The DRX beds also separate in the middle, allowing two sides to slide apart and out for easy serviceability.

- Bed rating: Up to 25 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Sand and Gravel

Exclusive Velocity Reduction Technology™, Impact Bars and Isolation Mounts deaden rebound forces for reduced spillage and material degradation. The DRX beds also separate in the middle, allowing two sides to slide apart and out for easy serviceability.

- Bed rating: 25- 100 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Hard Rock Mining and Limestone Quarrying

Exclusive Velocity Reduction Technology™, Impact Bars and Isolation Mounts deaden rebound forces for reduced spillage and material degradation. The DRX beds also separate in the middle, allowing two sides to slide apart and out for easy serviceability.

- Bed rating: 100- 200 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Coal-Fired Plants, Coal Prep Plants and Load-out Facilities

Exclusive Velocity Reduction Technology™, Impact Bars and Isolation Mounts deaden rebound forces for reduced spillage and material degradation. The DRX3000 is for extreme-impact impactions and includes Impact Energy Absorbers that compress up to 75mm to disperse impact energy.

- Bed rating: 200- 400 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Any operation that combines large material size and extreme height

Modular beds are based on a 600 mm sectional footprint which allows you to control your impact zone design by using an all-bar section in high-impact areas and a slider impact section where you require lower impact resistance or sealing. When both styles are used together you can achieve ultimate performance in your load zone.

- Bed rating: Up to 25 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Sand and Gravel

Modular beds are based on a 600 mm sectional footprint which allows you to control your impact zone design by using an all-bar section in high-impact areas and a slider impact section where you require lower impact resistance or sealing. When both styles are used together you can achieve ultimate performance in your load zone.

- Bed rating: Up to 200 kg/m

- Belt width: 600-1800mm

- Max belt speed: 5 m/s

- Applications: Hard Rock Mining, Limestone Quarrying and Load-out facilities

Helpful Resources

How to Select the Right Impact Bed

Belt damage and spillage are just two of the consequences of choosing the wrong impact protection in your load zone. Our Impact Bed Calculator can help you make the right decisions for your application.

Combatting Belt Conveyor Spillage: How to Properly Maintain your Load Zone and Minimise Downtime