Join Flexco at

Booth #B35057!

Discover the latest developments in Light-Duty belt conveyor solutions in Atlanta at IPPE 2025

Flexco is Atlanta Bound!

The Flexco Light-Duty team is thrilled to join industry leaders in Atlanta, GA, for IPPE 2025!

Visitors to Booth #B35057 will have the opportunity to explore our innovative solutions for food processing, including our Food Grade Belt Cleaners, Novitool® Endless Splicing Systems, and other belt conveyor technologies.

For more details about our booth and what to expect, check out the event information below!

Solutions On-Display at IPPE 2025

From new additions to old favorites, the Flexco Booth has a belt conveyor solution for everyone.

Discover what you can find at our booth below.

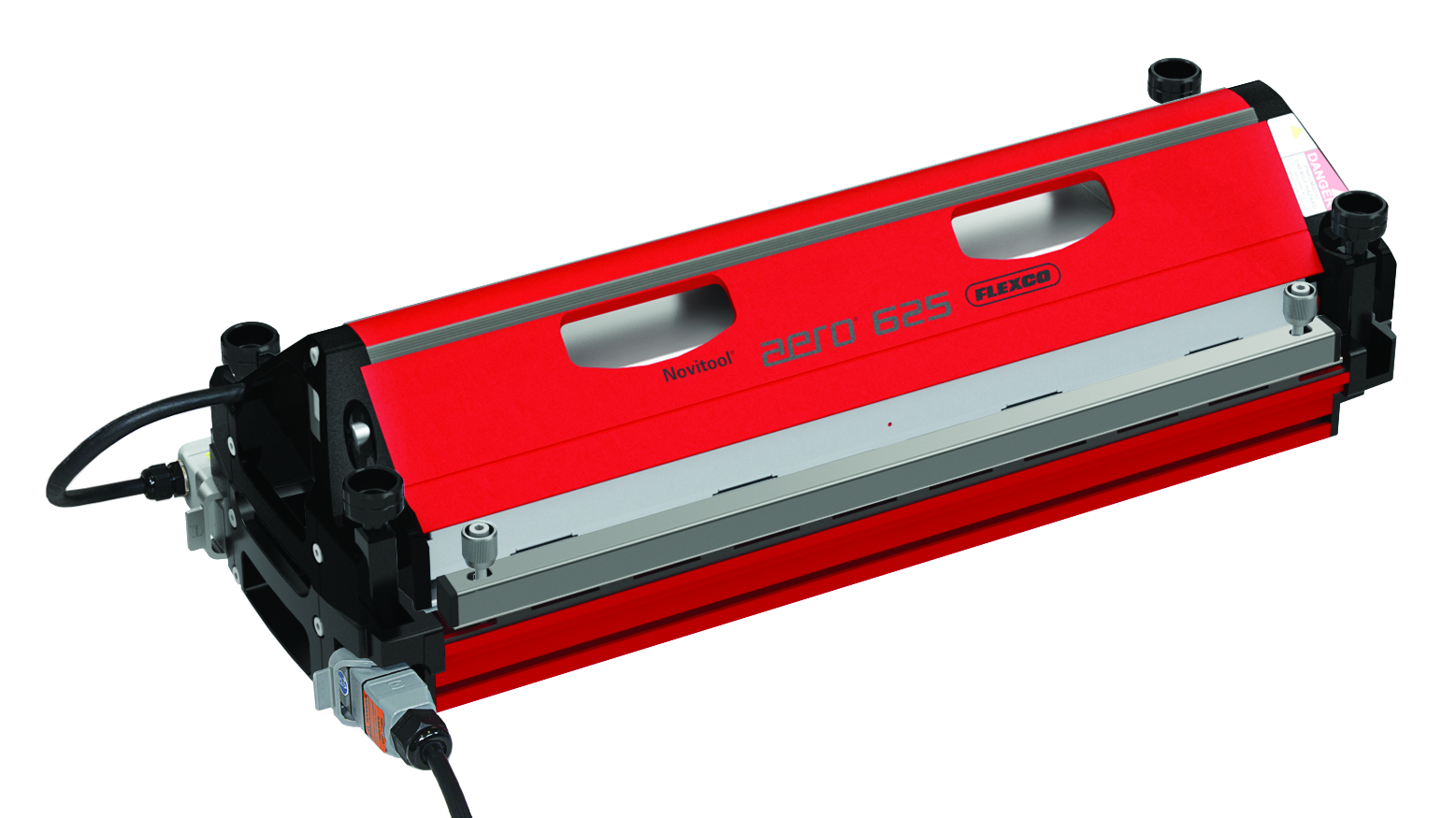

Novitool® Aero® Splice Press

Available for Product Demo

Designed for speed and precision, the Novitool® Aero® Splice Press allows maintenance teams to complete splices in less than 10 minutes, ensuring minimal downtime and maximum productivity. With all necessary components compactly self-contained, the Aero is easy to use, store, and transport, making it ideal for fast-paced food production environments. And, its precise temperature and pressure controls deliver reliable, hygienic splices that meet the rigorous standards of food safety.

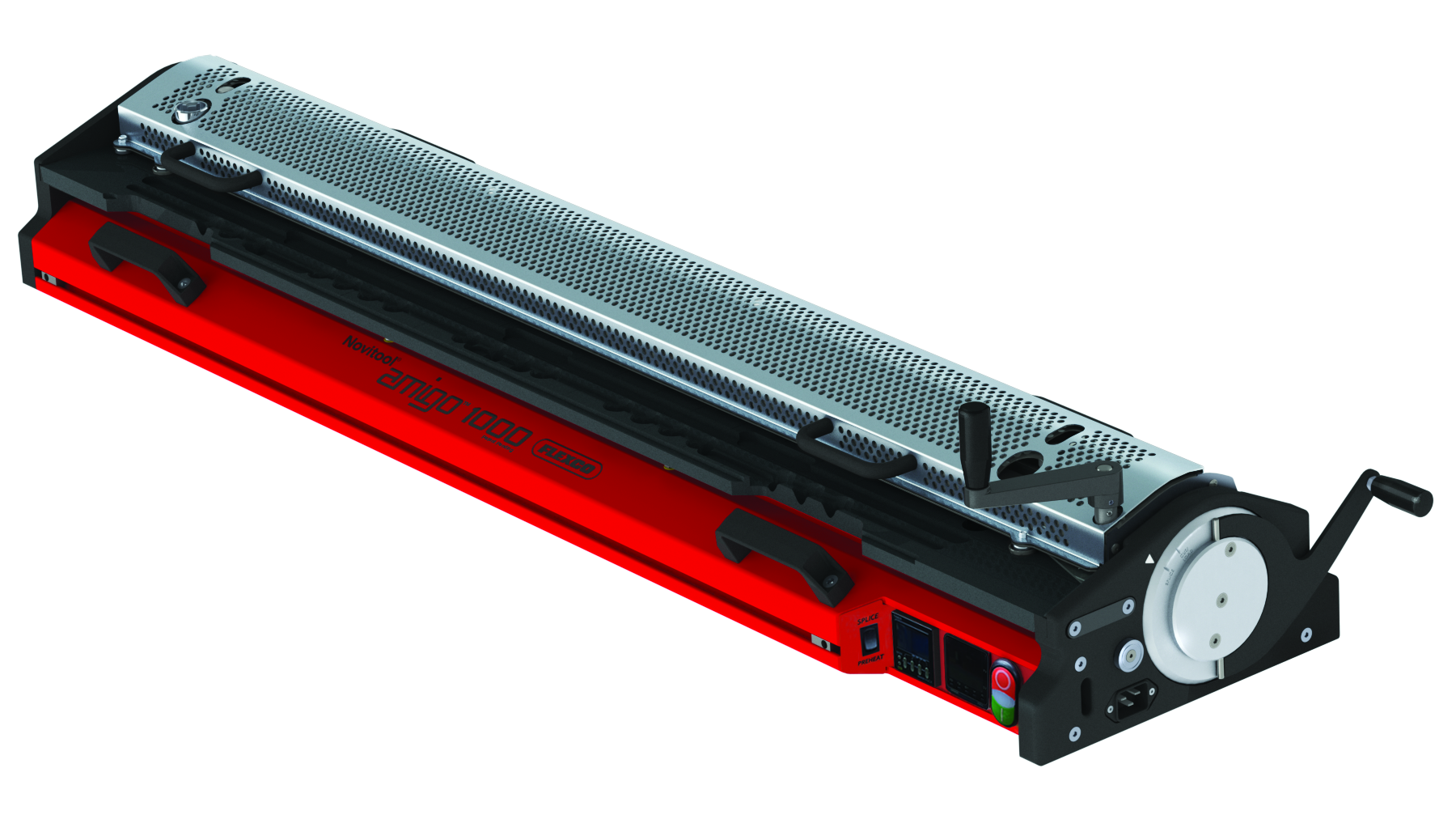

Novitool® Amigo™ Splice Press

Available for Product Demo

The Novitool® Amigo™ Splice Press is specifically designed for splicing monolithic belting in food processing environments, ensuring precision and reliability. By delivering tight pitch tolerance and eliminating pinholes, the Amigo creates hygienic, seamless splices that meet strict food safety standards. With its integrated focus on accuracy, speed, and operator safety, the Amigo is the perfect solution for both in-shop and on-site splicing.

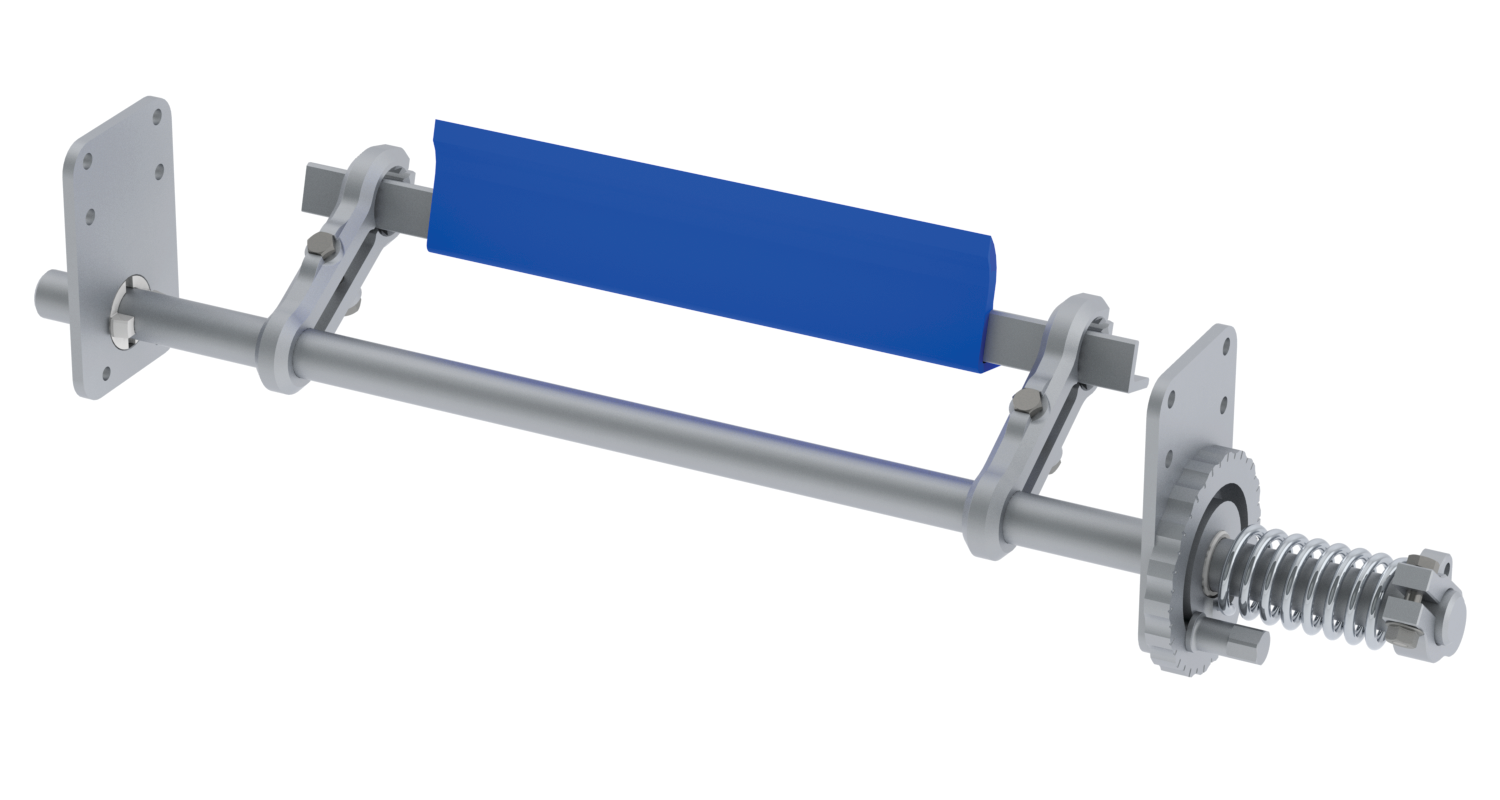

FGP-ES Food Grade Primary Cleaner with External Spring

Mounted at the head pulley, the FGP-ES is engineered for maximum hygiene and ease of maintenance. With an exposed external spring, its design ensures thorough cleaning and simplified upkeep. Perfect for highly sanitary applications in beef, pork, and poultry processing, the FGP-ES excels on homogenous or modular belting, helping facilities meet rigorous food safety standards while maintaining optimal belt cleanliness and performance.

FGS Food Grade Secondary Cleaner

Designed for efficiency and hygiene, the FGS features solid stainless steel components for durability and easy maintenance. Its quick disassembly ensures seamless cleaning and sanitation, minimizing downtime and keeping operations running smoothly. The FGS is equipped with FDA-compliant food grade blades available in white, blue, metal detectable blue, and metal detectable dual durometer blue, making it an ideal choice for food processing facilities prioritizing safety and performance.

Alligator® Staple Fastening System

The Alligator® Staple Fastening System is the go-to solution for light- and medium-duty conveyor belt applications. Engineered for efficiency, this system features one-piece fastener strips with pre-inserted staples, making installation quick and hassle-free. By minimizing downtime and simplifying maintenance, the Alligator® Staple System ensures your operation stays productive and your belts run smoothly.

Roller Lacer® Gold Class™

The Roller Lacer® Gold Class™ revolutionizes belt maintenance by delivering easier, more secure, and safer installation of Clipper® G Series™ and Wire Hook Fastening Systems. Designed for precision and efficiency, the Roller Lacer® Gold Class™ ensures consistent splices that maximize belt performance while reducing installation time and operator strain. Perfect for demanding applications, this Roller Lacer helps keep your operation running smoothly and your team working safely.

Laser Belt Square

The Laser Belt Square simplifies belt squaring with unmatched speed, and precision. In just seconds, it identifies the belt edge, aligns the laser, and projects an accurate line for marking and cutting. Perfect for splicing preparation, the Laser Belt Square ensures consistent, reliable results, reducing downtime and enhancing overall efficiency.

Meet the Light-Duty Team at Booth #B35057

Key members of the Flexco Light-Duty team will be in attendance at IPPE 2025.

See which experts you can expect to meet in our booth below.

Industry Manager | Food Processing

Patrick Roach

Accounts Manager | Food & Beverage

As Strategic Accounts Manager for Flexco, Patrick Roach delivers belt conveyor solutions tailored to the light-duty sector and helps to implement strategies that address key pain points such as package damage, belt mistracking, sanitation concerns, and maintenance inefficiencies.

Product Manager | Light-Duty BCP

Michelle Graves

Product Manager | Endless Splicing

Graves manages the overall global business, market plans, technical support, and activities associated with the light-duty belting market for the Novitool product line, including new product development, market analysis, and global strategy.

Dan Tuttle

Product Manager | Light-Duty MBF

As a Product Manager for Flexco, Tuttle oversees Flexco Light-Duty Mechanical Belt Fastener product offerings, manages day-to-day operations, and provides critical strategic ideology and implementation strategies that better meet the needs of our extensive customer base.

Follow Flexco at IPPE 2025!

For up-to-the-minute updates of Flexco's presence from the show floor at IPPE 2025, be sure to follow along on our social media channels!

Our subscribers will get a first-look at behind the scenes booth videos, new product demonstrations, fun Flexco team moments, and so much more.

If you visit us at IPPE 2025, be sure to tag us on social media with #Flexco!

Check out our social media profiles below: