Flexco Elevate™ is an innovative, real-time belt cleaner monitoring system that harnesses the power of predictive analytics so mining operations can remotely gather critical insights that optimize belt conveyor productivity and heighten operational efficiencies. At the show, Flexco will be using a live, interactive dashboard to showcase how the Flexco Elevate™ wireless platform transfers data insights to an intuitive, cloud-based dashboard via edge technology, allowing remote monitoring of belt cleaners.

New for MINExpo® 2021 is Flexco’s toughest staple fastener. Demanding mining environments require a superior belt splice like the Flexco® XP™ Staple splice, which provides Xtreme performance with solid woven PVC and PVG type belts. Unlike similar designs, the XP sets one fastener at a time so misdrives and tool jams are infrequent. Should an occasional misdrive occur, the design allows the operator to skip over it and continue with the splice. At this year’s show, we will be demoing the XP Staple Belt Fastening System, along with a variety of other splicing solutions.

Another product debuting at MINExpo under the Flexco line of mechanical fastening systems is the Super-Screw® Flexible Rubber Fastening System. Offered as part of a strategic partnership in North America with MLT Minet Lacing Technology, Super-Screw offers a faster and easier alternative to vulcanization since it can be installed regardless of the location or accessibility of the conveyor belt and in any weather condition. We’ll be showing attendees how to install a Super-Screw splice throughout the show in the demo area of the Flexco booth.

Also new to the Flexco product line as an addition to our line of rip repair solutions, is the Fix’N Go® Rip Repair System – the answer for quick and permanent belt repair that gets your belt back up and running with limited downtime. Fix’N Go can be installed regardless of conveyor access and weather conditions, day or night, with self-tapping screws that separate carcass threads without severing them. Stop by the booth to see our rip repair solutions being demoed live throughout the week.

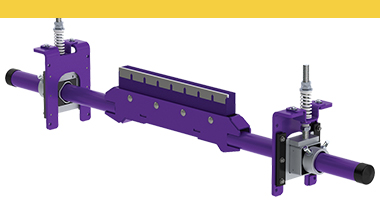

The MXS Extreme-Duty Secondary Cleaner is the perfect complement to our MXP Extreme-Duty Precleaner, with the duo acting as a total cleaning solution along the beltline in the most extreme mining applications. Handling belt speeds up to 2000 fpm (10 m/s) and belt widths from 42” to 120” (1050 to 3000 mm), the rugged, oversized mainframes can withstand extreme pressures, while the built-in lift points and modular design make it easier to carry and install. At MINExpo, check out our “extreme” display of the largest, toughest cleaner on the market.

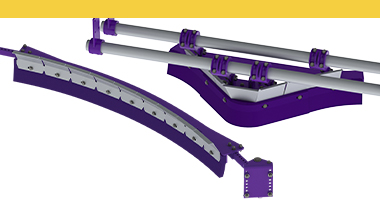

The unique design of the blades on the new MXD Diagonal and MXV V-Plows will be sure to draw you in to the Flexco booth at MINExpo. Capable of handling the harshest materials in the mining industry, these plows provide all the strength needed for belts with large tonnages. The design also ensures that extra care has been taken to ensure the tail pulley is protected and material does not slip under the plow or jump over it.

If superior cleaning efficiency and low maintenance are two things you check off your list when searching for a cleaning solution, make sure you stop by the Flexco booth at MINExpo to check out our CBS Continuous Blade Secondary Cleaner. The heavy-duty blade features a steel backbone holding a carbide leading edge, which is encapsulated in our proprietary polyurethane to provide a long-wearing solution for your belt. When paired with a spring or air tensioner, the blade maintains constant pressure on the belt for excellent cleaning efficiency.

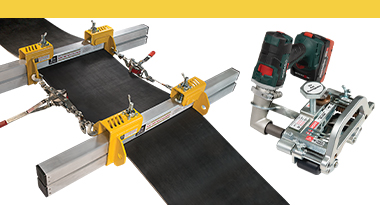

We know safe and quick installation begins with proper belt preparation. That’s why we’ll have our new 6- and 8-ton TUG™ HD® Belt Clamps on hand at this year’s show, along with the new Powered FSK™ Skiver. Your crew will be safer when their belts are secured with TUG HD Belt Clamps, which provide even tensioning across the entire width of the belt for ultimate strength. And your splices will be stronger and last longer when you use the Powered FSK Belt Skiver to remove the top cover and properly seat the fasteners in the belt.

Maintenance teams are constantly assessing their systems, but there is no substitute for having an expert third party share tips, tricks, and best practices. Every day, Flexco field specialists around the world are helping on-site maintenance teams identify the root cause of issues, and finding long-term solutions before they threaten to become major problems. Stop by our booth to chat with one of our experts about how we can help you maximize your operation’s productivity.

Copyright Flexco