Here’s how it works.

Step 1: Submit Proactive Maintenance Plan Request

After filling out our Proactive Maintenance Plan Request form, your local Flexco Territory Manager will analyze your needs and reach out with further instructions.

Step 2: Send in Your Flexco Equipment

Once approved, our Territory Manager will send you shipment information, and your team will be required to send in all pieces of your endless splicing system.

Step 3: Assessment and Diagnosis

When in hand, our dedicated team of product technicians will analyze your product, making note of potential discrepancies and creating a full report on the health of your tool.

Step 4: Achieve Peak Performance

With your results in mind, our team will work with yours to craft an action plan to make repairs and replacements, and generate best practices for your shop.

Don't let your team get caught on-site with faulty equipment; keep your customer relationships strong with healthy splicing tools from the Flexco Proactive Maintenance Plan.

Proactive Maintenance Plan Request

The next steps.

By utilizing Flexco's Proactive Maintenance Plan, distributors, belt shops, and end-users can better ensure that the tools they have while on-site work when they need them most.

After filling out our Proactive Maintenance Plan Request form, your local Flexco Territory Manager will analyze your needs and reach out with further instructions.

Key Features of Flexco's Proactive Maintenance Plan

The Flexco Proactive Maintenance Plan ensures your splice operators are never caught off guard by faulty equipment when they need it most. By addressing potential issues early, you can take control of your operation’s reliability and keep your team ready to deliver results every time.

Don’t wait for a warning—by the time your equipment signals a problem, it may already be too late. Thinking ahead helps you prevent downtime, avoid costly delays, and ensure your tools are in peak condition well before they’re put to use.

Safeguard your team’s efficiency, prevent missed opportunities, and maintain your competitive edge by keeping your equipment running like new. Choose Flexco’s Proactive Maintenance Plan today.

Repair Discounts

Save on repairs with a 10% discount on service costs through 12/31/2026. Simply reference promo code REPAIR10 when submitting your Proactive Maintenance Plan Request Form above.

Trade-In & Trade-Up

Upgrade your equipment and save. Trade in any working competitor’s air-cooled/water-cooled press or older Novitool® press for a 10% discount off the distributor net price of a new Aero® press unit.

Limit one trade-in per new press.

Eligible Products for the Flexco

Proactive Maintenance Plan

Have a Flexco product that is in need of maintenance, or just want to better prepare for future downtime incidents? See which of our solutions are currently eligible for the Flexco Proactive Maintenance plan below!

Belt Clamps

Keeping conveyor belts secure for product installation and repair is crucial for worker safety. Without a properly maintained clamping system, operators may have to work in unstable conditions, leading to potentially catastrophic injuries.

Which Belt Clamps are available for the Proactive Maintenance Plan? See below:

- SmartClamp™

- Far-Pul™ HD®

- TUG™ HD®

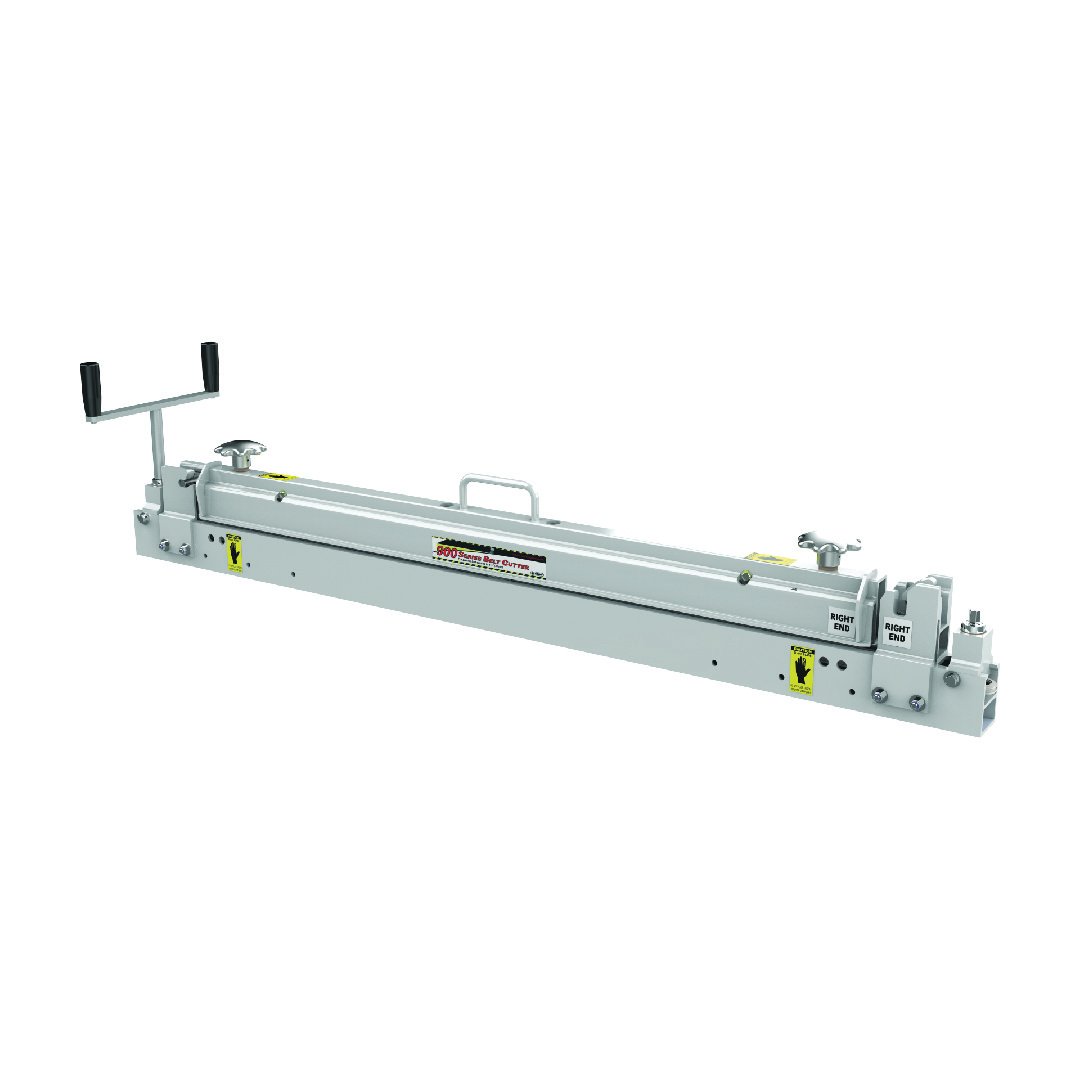

Belt Cutting and Prep Tools

Properly cutting and prepping conveyor belts helps to ensure that fastener installation and the conveying process can run smoothly. Failing to do so can lead to mistracking and problems with any preinstalled belt cleaning systems.

Which Belt Cutters are available for the Proactive Maintenance Plan? See below:

- 900 Series Belt Cutter

- FSK™ Belt Skiver

- Electric Belt Cutter

- Alligator® Staple Gold Class™ Plus

Endless Splicing Tools

Achieving a truly seamless splice for light-duty conveyor applications is a top priority. Poor splice quality is a risk for belt failures, leading to costly downtime that limits production, capacity, and profitability.

Which Endless Splice Systems are available for the Proactive Maintenance Plan? See below:

- Novitool® Aero® Splice Press