car·ry·back | \ ˈker-ē-ˌbak

noun: material that sticks to the conveyor belt and either falls onto the floor or continues on the belt and adheres to other conveyor components.

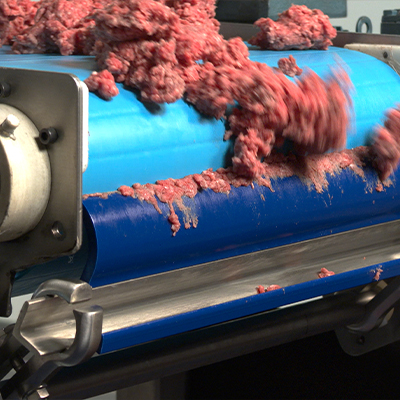

The operations manager at a well-known beef processing plant was watching product fall on the floor every day when a homemade cleaner that wasn’t getting the job done. After conducting a Waste Walk with his team, he was even more discouraged and decided to get more serious about his carryback problem. The material that was dropping off his belts and considered inedible was adding up to 50-60 lb. daily. At an average cost of $2/lb., this was adding up to $100 in product waste each day.

After discussing the issues with his maintenance team and learning that the fixed UHMW cleaner wasn’t keeping the blade on the belt to scrape off material, he decided to look for an engineered belt cleaner that was designed specifically for food applications.

Discussions with a local Flexco distributor partner led the operations manager and his maintenance team to the Flexco Food Grade Secondary Cleaner. Made from FDA-compliant materials, the cleaner featured a simple design that was easy to assemble and disassemble for routine maintenance. But most important to the maintenance crew was the easy-to-operate and adjust tensioning system that allows them to maximize the cleaning efficiency with consistent blade-to-belt contact. In other words, no more carryback.

The results were more than the operations manager could have wished for, with added benefits that were not even considered when on the Waste Walk. First, and most importantly, carryback was reduced and production was increased. The 50-60 lb. of product loss per day was a thing of the past. At a plant running 365 days a year, the addition of one cleaner represented a $36,500 savings. It also meant less time spent by the maintenance crew on sanitation of belts and components. An added benefit was the solid, stainless steel components that limited crevices and opportunities for bacteria growth – a stark contrast to the bolted-on design on the homemade cleaner

Find out more by downloading our Waste Walk checklist. Or invite a Flexco representative to your operation and we’ll walk side-by-side with your maintenance team to conduct a Waste Walk Assessment on your conveyors.

Copyright Flexco