Download our Whitepaper

Mistracking Belts: Examining the Causes and Solution

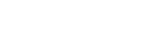

Say goodbye to belt misalignment with our high-performance tracking idler, the PTEZ Belt Trainer. Employing our unique “Pivot and Tilt” feature using our patented PTEZ mechanism, the unit responds and compensates immediately to belt misalignment using the tapered end roller profile to engage the training action. This ensures that the belt stays away from the structure and the material stays on the belt without the use of sensors or edge rollers.

Developed for return-side mistracking, the PTEZ features Flexco's patented 'Pivot-and Tilt' technology to track the belt without the use of sensor rollers. This design provides friction and changes the tension profile of the belt. When both the pivoting and tilting mechanisms work together, they are more than three times as effective as restoring belts back to the centre of the conveyor. The unit also has a polyurethane roller cover to ensure a long-lasting performance.

The trainer can be seamlessly integrated into a wide range of applications and conditions. This includes single-direction and reversing belts, wet or dry conditions, belts with edge damage or wear, belts experiencing misalignment on one or both sides, as well as mechanically fastened or vulcanised belts.

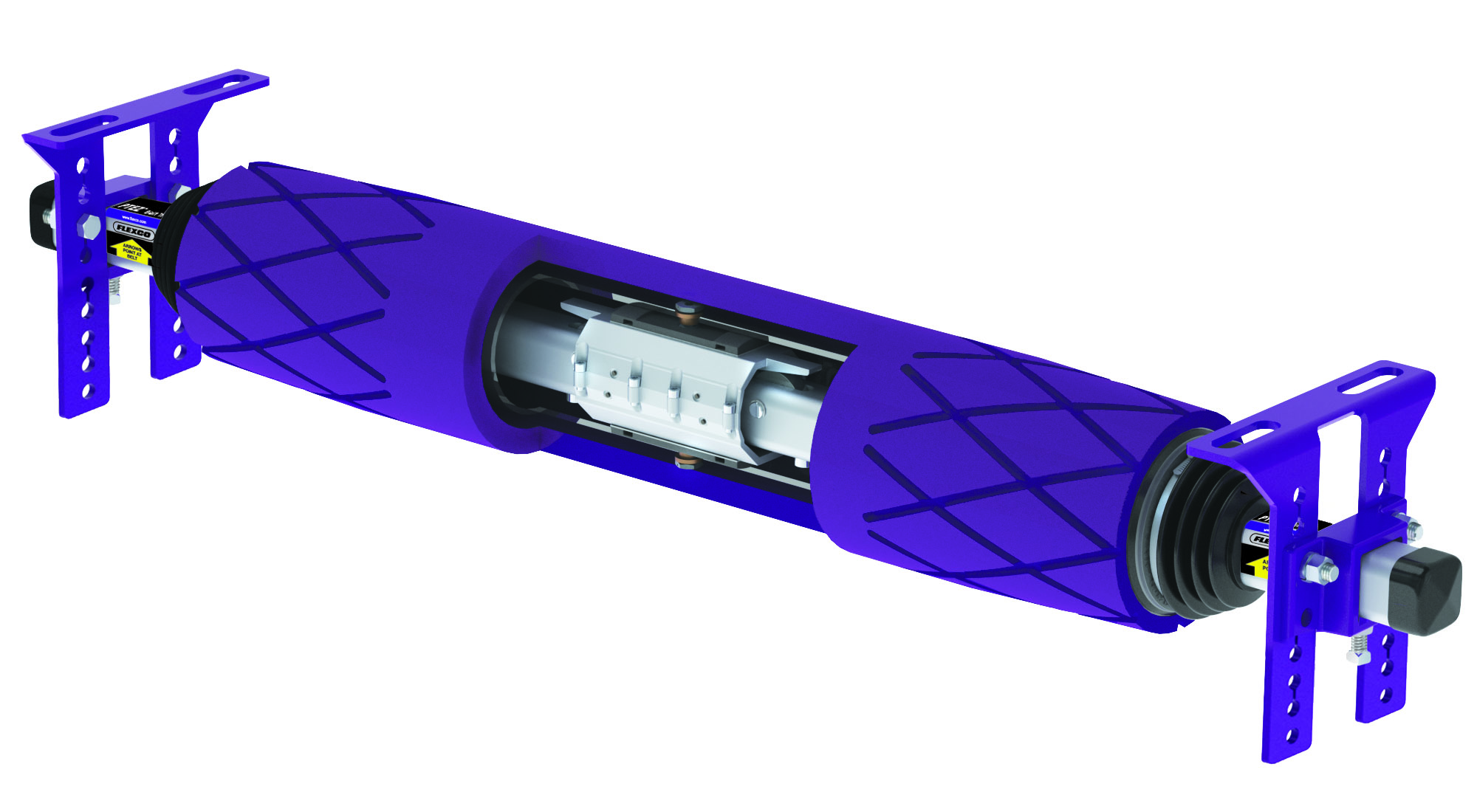

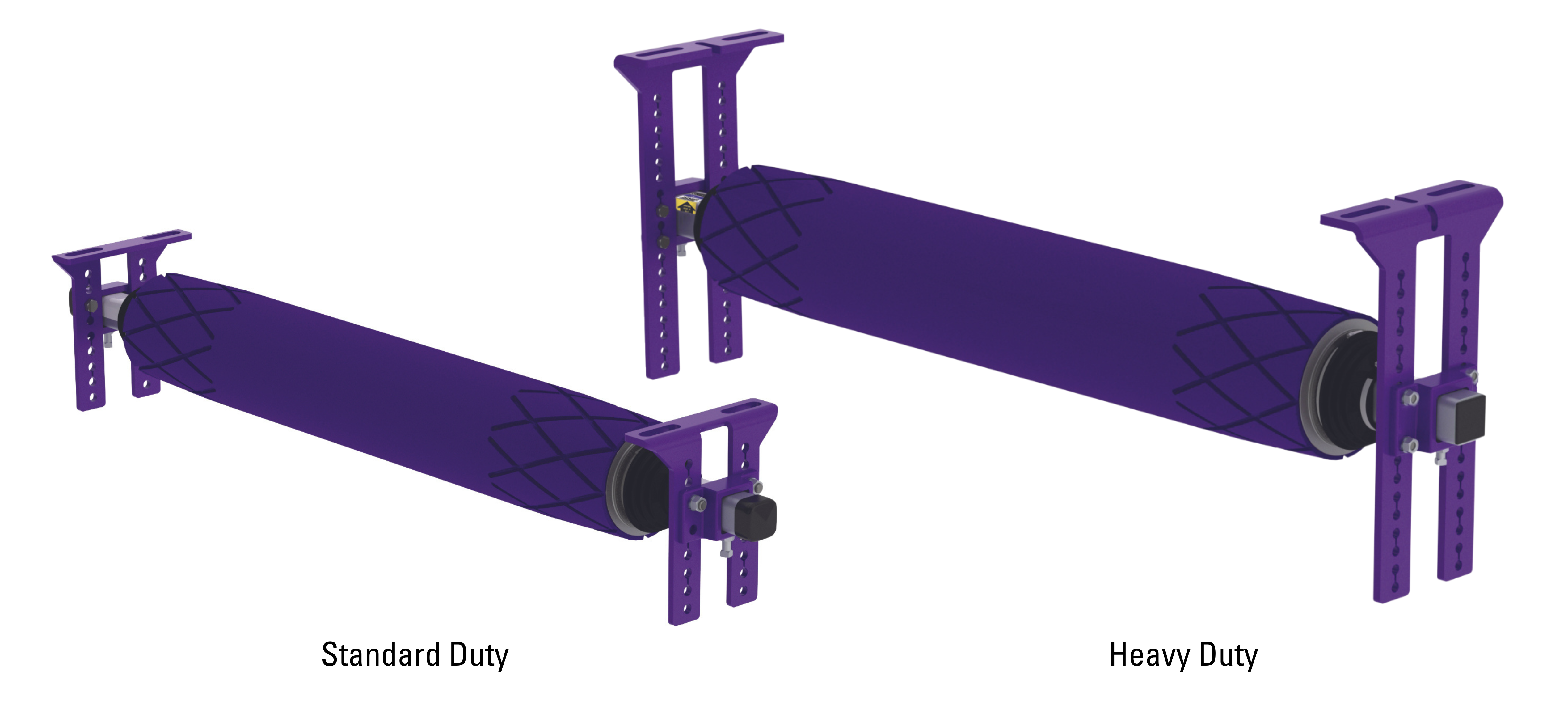

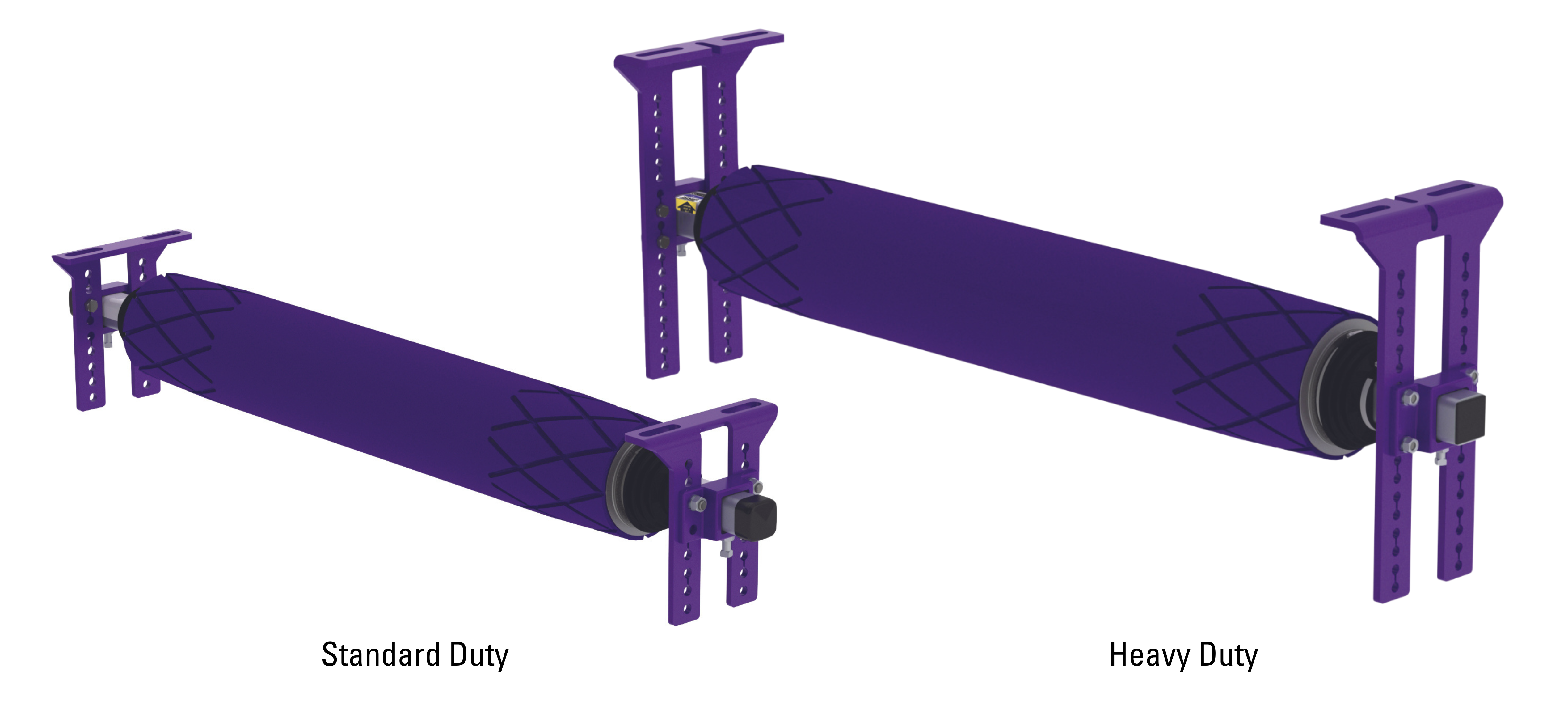

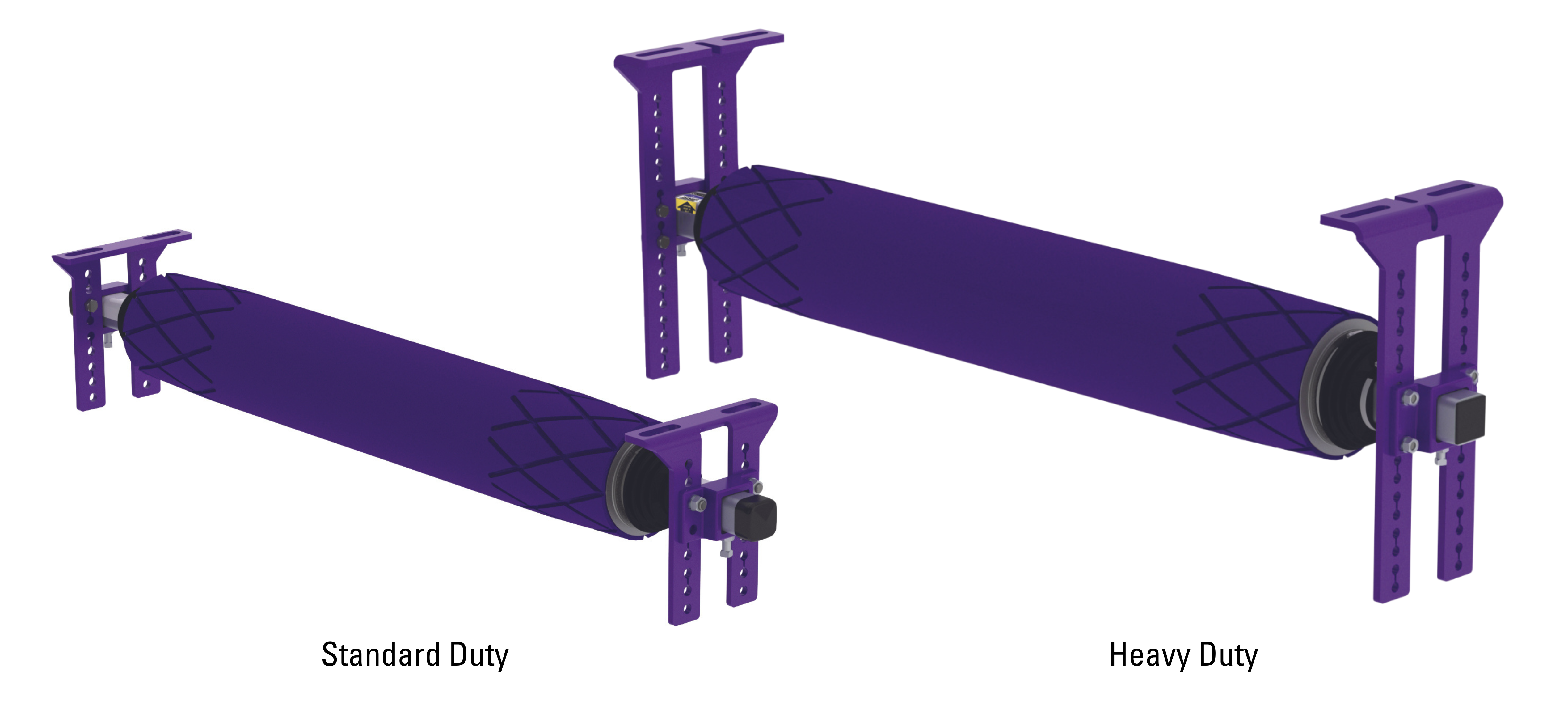

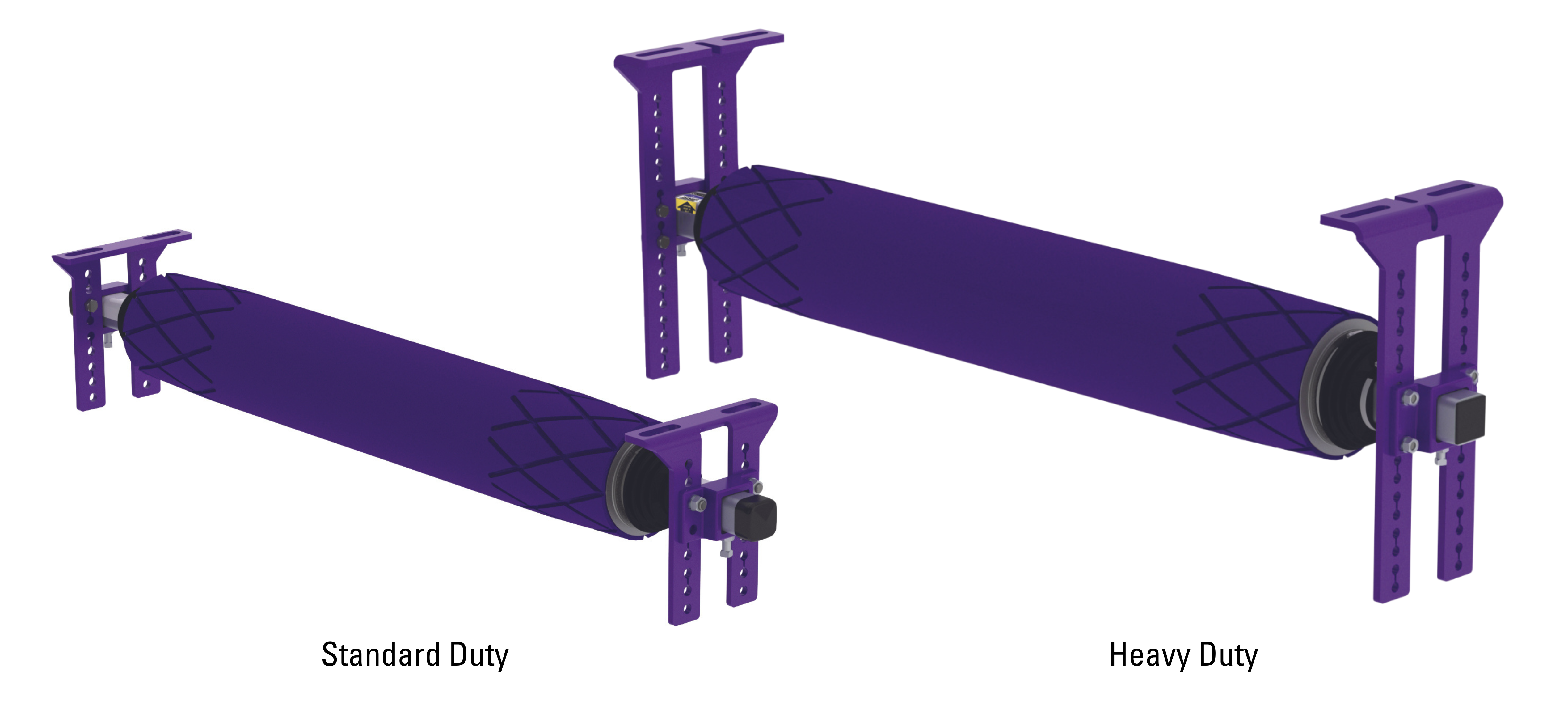

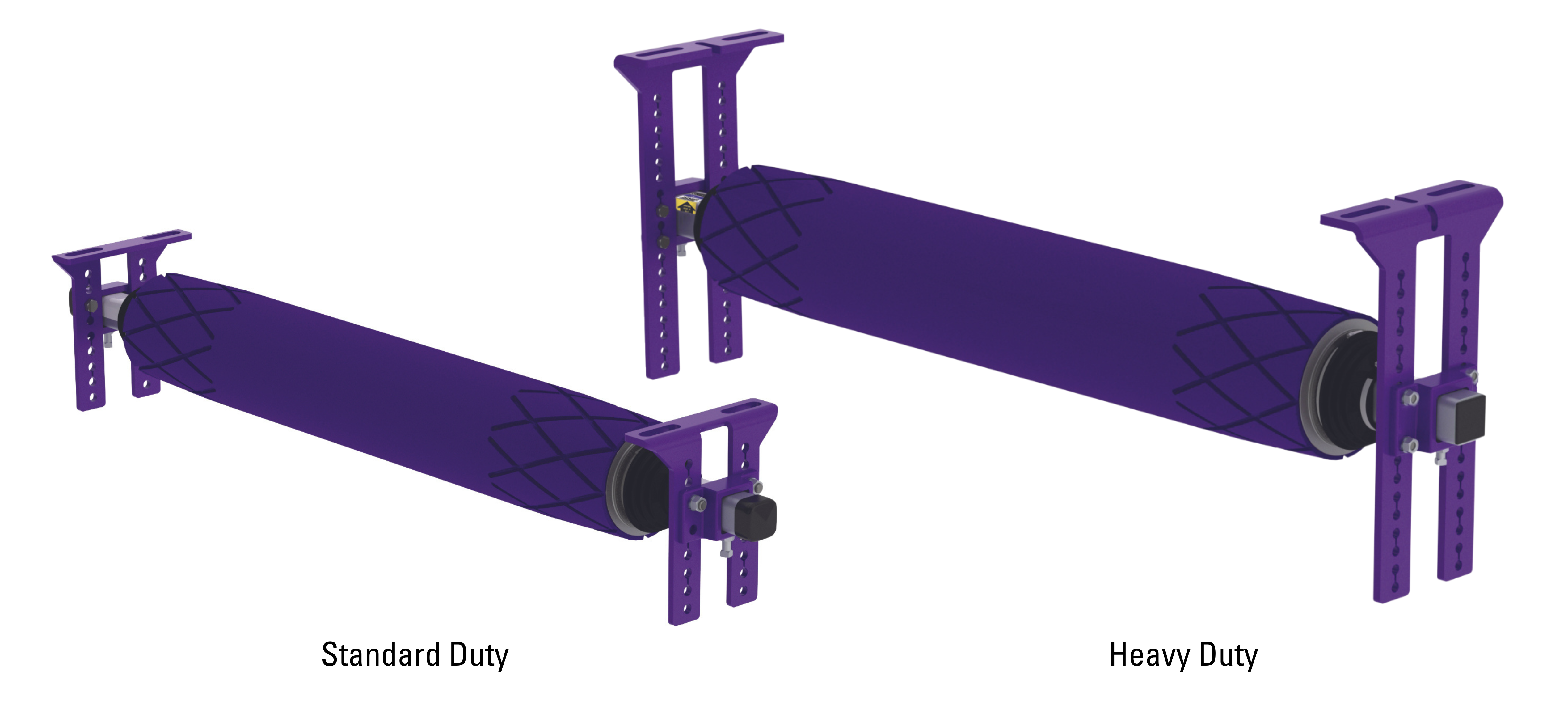

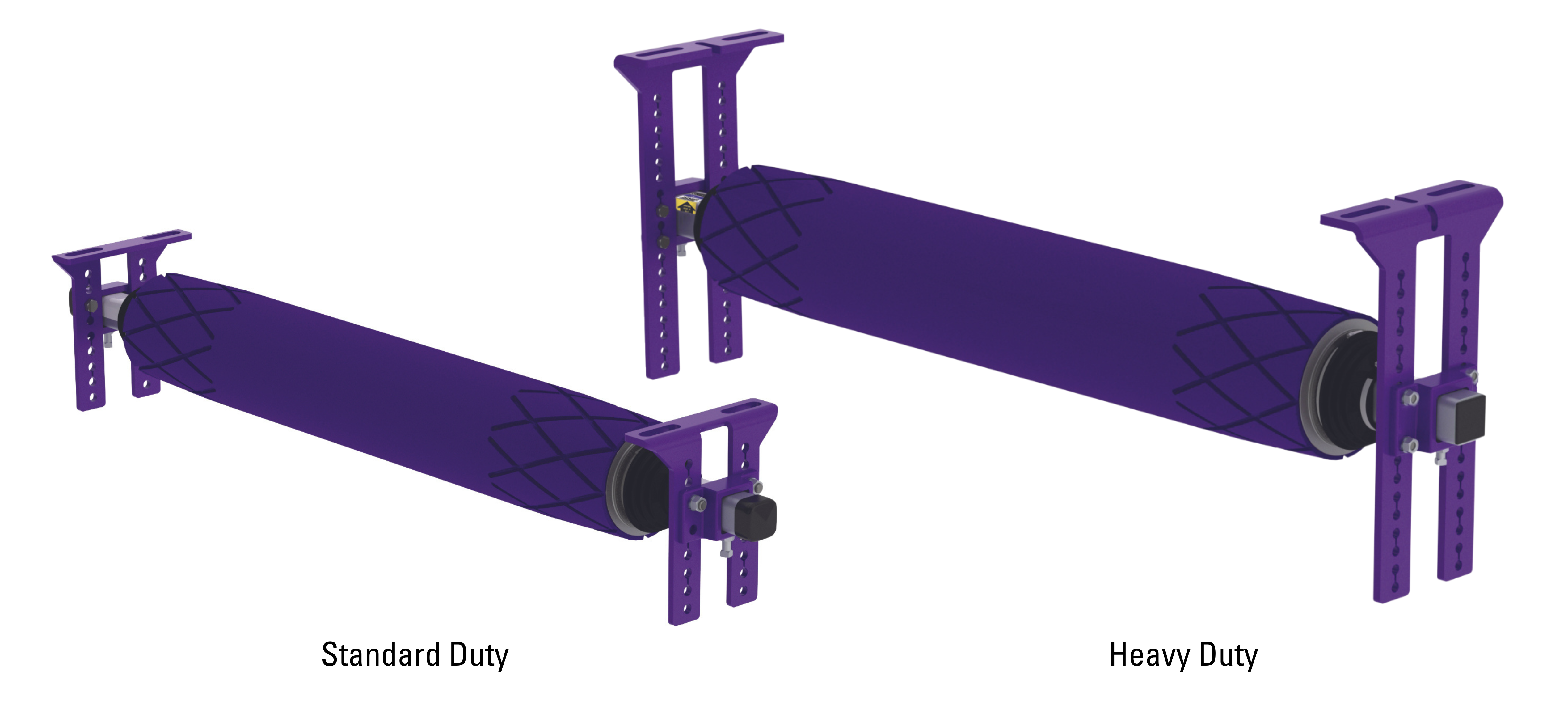

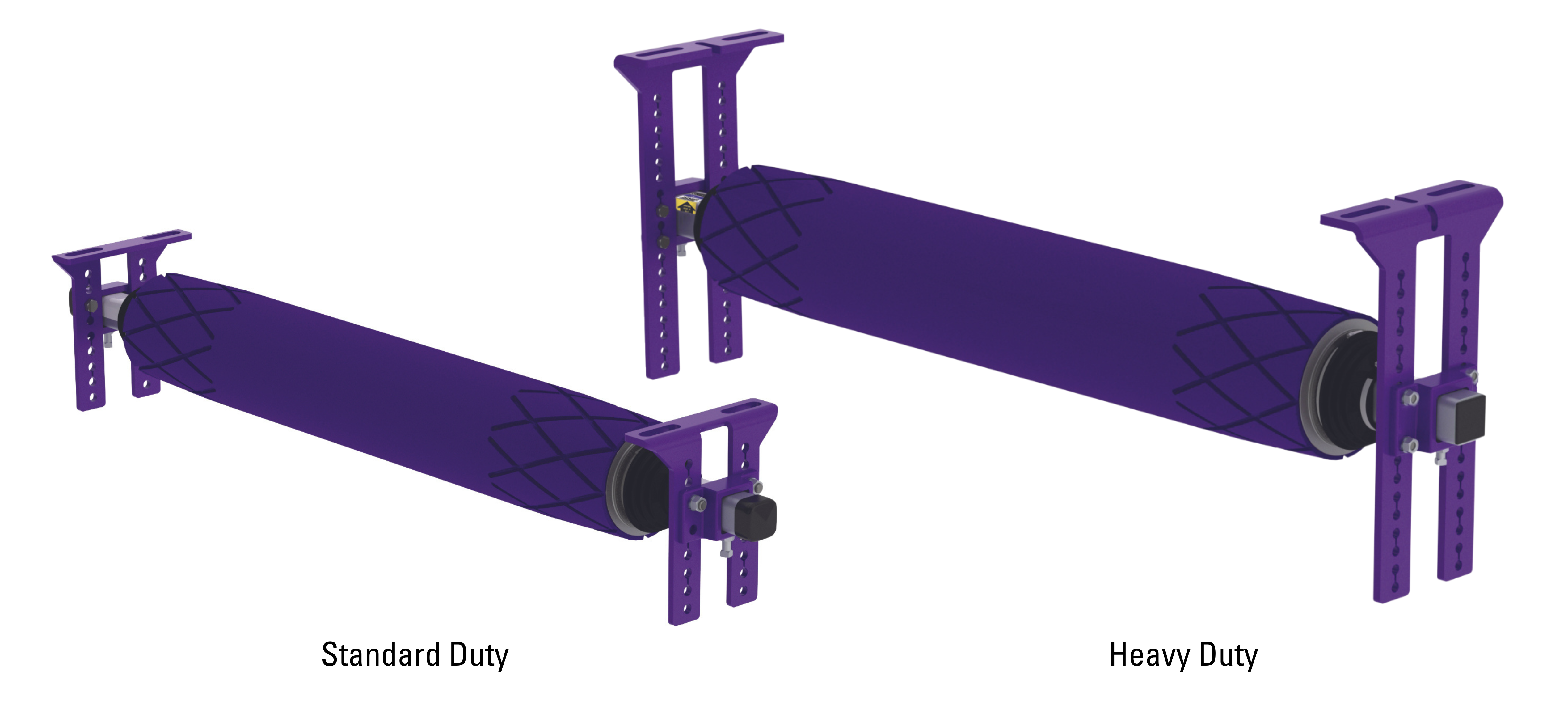

The simple, adjustable mounting brackets ensure quick and accurate installation. The trainer has versatile mounting options including a standard pull-up mountin g position or it can be installed on the clean side of a return belt if the belt is cupped.

Standard-Duty is available for belt widths 450 to 1200mm and up to 1600 PIW maximum tension. Heavy-Duty is available for belt widths 1050 to 2100mm and up to 2400 PIW maximum tension. The Heavy-Duty option has stainless steel components for superior corrosion resistance.

Developed for return-side mistracking, the PTEZ features Flexco's patented 'Pivot-and Tilt' technology to track the belt without the use of sensor rollers. This design provides friction and changes the tension profile of the belt. When both the pivoting and tilting mechanisms work together, they are more than three times as effective as restoring belts back to the centre of the conveyor. The unit also has a polyurethane roller cover to ensure a long-lasting performance.

The trainer can be seamlessly integrated into a wide range of applications and conditions. This includes single-direction and reversing belts, wet or dry conditions, belts with edge damage or wear, belts experiencing misalignment on one or both sides, as well as mechanically fastened or vulcanised belts.

The simple, adjustable mounting brackets ensure quick and accurate installation. The trainer has versatile mounting options including a standard pull-up mountin g position or it can be installed on the clean side of a return belt if the belt is cupped.

Standard-Duty is available for belt widths 450 to 1200mm and up to 1600 PIW maximum tension. Heavy-Duty is available for belt widths 1050 to 2100mm and up to 2400 PIW maximum tension. The Heavy-Duty option has stainless steel components for superior corrosion resistance.

![]()

![]()

When a Flexco Heavy-Duty Conveyor Specialist conducted an audit on the affected conveyors, he suggested that they try the HD PTEZ. The site learned about the Pivot and Tilt technology and was excited to try it.

![]()

The mistracking was immediately corrected once the HD PTEZ was installed. Since the installation of the trial units, the site purchased several more belt trainers for other conveyor belts.

Mistracking Belts: Examining the Causes and Solution

The best way to tackle a mistracking issue is to find the source of the mistracking. Is product buildup on your idlers or frame causing your belt to wander one way or the other? Is it a structure problem caused by heavy equipment bumping the conveyor and causing the belt to mistrack? Is the belt’s splice not square?

An assessment of your entire conveyor system is the best way to evaluate the cause of the mistracking.

Assess your issue

Fill out the form below to register for a free assessment of your belt conveyor system by a Flexco Field Specialist.