The sales and service team at Flexco has seen its fair share of pulp and paper mills and spoken to hundreds of operators and maintenance personnel. Among their top complaints? Spillage. During visits, we continually hear and see material spillage and buildup are either preventing conveyor operators from doing their jobs well, or preventing the maintenance teams from performing routine inspections on equipment. Some even went as far to say the threat of fire and explosion keeps them up at night.

So what causes the spillage that keeps so many of you from getting that beauty rest you so desperately need? Most of the time, it’s due to an ineffective seal between the belt and the skirting. This allows materials like wood chips, hog fuel, and dust to escape from the load zone.

This buildup can close off important walkways and pile up on surrounding equipment, making access for maintenance and inspections difficult and possibly damaging other conveyor components by caking them with material. The spilled material requires manpower for cleanup as well – hours being taken away from more proactive and scheduled maintenance tasks.

But the most concerning thing about spillage is that all these materials are flammable. If they escape the load zone and build up near heat sources, fires and explosions can happen.

If spillage is causing you sleepless nights, Flexco can help. Fill out the form below and one of our Territory Managers will come out to assess your load zone to see how we can help you eliminate spillage.

An easy thing you can do to solve this problem is adjust the skirting to seal up the load zone. But unfortunately, not all skirting is adjustable, leaving you in a jam. But all is not lost. Flexco designs all its load zone products to be maintenance-friendly and adjustable, making your spillage issues a thing of the past.

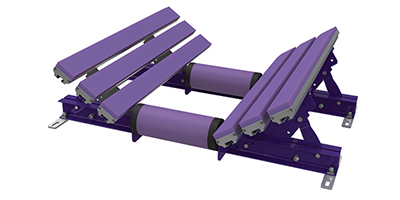

Flexco Slider Beds are engineered to provide containment around load zones. With long-lasting UHMW slider bars, combined with high-performance rollers, the Flexco Slider Bed effectively seals the load zone and minimizes drag on the belt. Slider beds can be paired with Flexco Impact Beds to create a holistic load zone system.

Spillage and dust aren’t just a nuisance in the pulp and paper industry, they’re a fire and health hazard. Use Flex-Seal™ Skirting paired with Urethane Skirting at any transfer throughout the wood yard where the load zone needs to be fully sealed to prevent chips, bark, and dust from escaping. This combination is especially effective at containing fugitive wood dust when paired with a Flexco slider bed. The Flex-Seal Skirting System creates a parallel seal with the belt to minimize the escape of material in your pulp or paper operation and the Urethane Skirting provides 3-4 times the wear life over typical rubber.

Flexco also offers Adjustable Impact Idler Sets for use between certain spans of impact beds. The idler sets use the same rollers we use in our slider beds. When used in conjunction with Flexco Impact Beds and Slider Beds, you can outfit your entire load zone with products designed with maintenance in mind.

Copyright Flexco